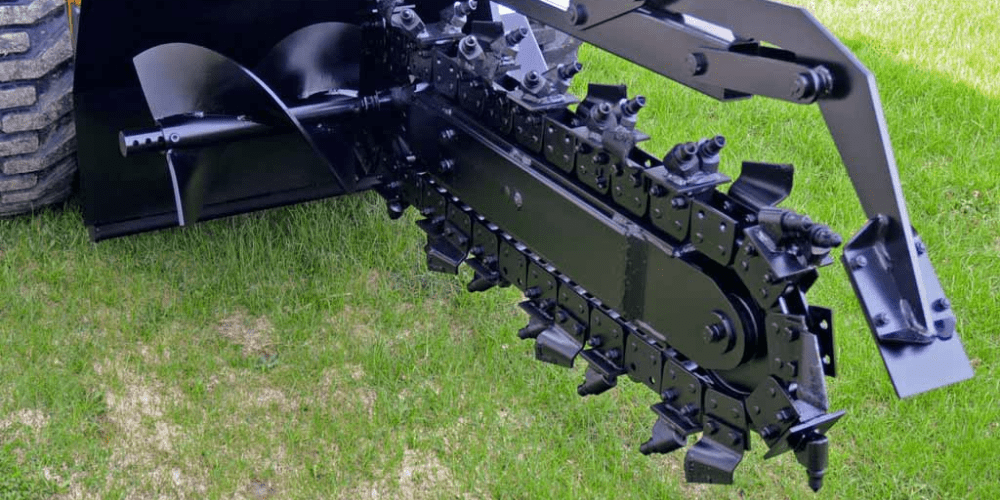

Rock teeth are highly effective for trenching in hard and rocky soil conditions. Trenching is a process of creating narrow, deep holes or trenches in the ground to install underground utilities, irrigation systems, and drainage systems. In rocky soil conditions, trenching can be a challenging and time-consuming process, but rock teeth can make it much easier.

Materials:

Rock teeth are made of tungsten carbide material, which is highly resistant to wear and tear. This makes them ideal for trenching in rocky soil conditions where other teeth may break or wear down quickly.

Advantages:

Rock teeth are designed with sharp cutting edges that can easily penetrate through hard and compacted soil, making it easier to create a trench.

Another advantage of rock teeth for trencher is that they are designed with a large surface area, which allows them to provide good traction and grip on the soil. This helps to prevent slipping and sliding during the trenching process, ensuring a smooth and efficient operation.

Nonetheless, rock teeth are highly effective for trenching in hard and rocky soil conditions. They offer durability, sharp cutting edges, and good traction, making them an ideal choice for contractors and operators who need to trench in challenging soil conditions.

Features of rock teeth for trenchers:

Rock teeth for trenchers are designed with several key features that make them highly effective for trenching in rocky soil conditions. Some of these features include:

Tungsten carbide material:

Rock teeth are made of tungsten carbide material, which is highly resistant to wear and tear. This makes them ideal for trenching in rocky soil conditions where other teeth may break or wear down quickly.

Sharp cutting edges:

Rock teeth are designed with sharp cutting edges that can easily penetrate through hard and compacted soil, making it easier to create a trench. The cutting edges are designed to be self-sharpening, which means they stay sharp for longer periods of time.

Large surface area:

Rock teeth are designed with a large surface area, which allows them to provide good traction and grip on the soil. This helps to prevent slipping and sliding during the trenching process, ensuring a smooth and efficient operation.

Conical or bullet shape:

Rock teeth are often designed with a conical or bullet shape, which allows them to easily penetrate through hard soil and rock formations. This shape also helps to reduce vibration and ensure a smoother drilling operation.

Versatility:

Rock teeth can be used in a variety of trenching applications, including foundation trenching, pipeline installation, and drainage systems. This versatility makes them a popular choice for contractors and operators who need a reliable and efficient trenching tool.

Similarly, the combination of tungsten carbide material, sharp cutting edges, large surface area, conical or bullet shape, and versatility make rock teeth highly effective for trenching in rocky soil conditions.